Switched Reluctance Motor Manufacturer

Our switched reluctance motor(SRM) uses reluctance torque for efficient control of speed and torque without permanent magnets or electric excitation magnets.

We also offer the switched reluctance BLDC motor, featuring high efficiency, compact size, and excellent reliability, making it ideal for a wide range of applications.

- Drive Voltage: 24V to 220V

- Phase Configuration: Single-phase, Two-phase, Three-phase

- Rated Speed Range: 18,000 RPM to 35,000 RPM

- Rated Torque: 0.22 N·m to 0.72 N·m

- Service Life: Minimum of 6,000 hours

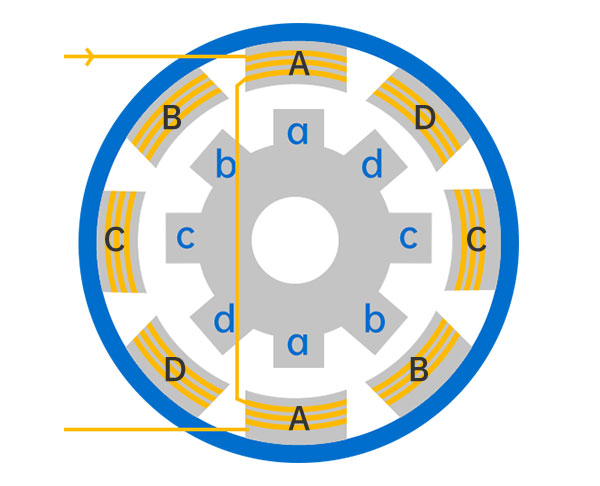

Switched Reluctance Motor Construction

Laminated stator windings, a solid rotor core, copper windings, and a control system are all components of a SRM motor.

- Stator: Laminated steel sheets with windings that create a rotating magnetic field.

- Rotor: A solid steel core with prominent poles that line up with the magnetic field of the stator.

- Windings: Copper windings in stator slots, energized sequentially to generate magnetic fields.

- Magnetic Pole Structure: Salient poles in rotor and stator create reluctance-based torque and motion.

- Power Supply: Delivers electrical pulses in a predetermined order to energize the stator windings.

- Control System: Controls the timing and switching of current for precise rotor movement.

Based on Design

For particular applications, our PMSRM, IPMSRM, and HRP-SRM switched reluctance motors provide excellent performance, torque, and efficiency.

Permanent Magnet Switched Reluctance Motor

- Permanent magnets in the rotor for better efficiency.

- Reduced cogging for smoother high-speed operation.

- Ideal for high-torque, energy-efficient applications.

Interior Permanent Magnet Switched Reluctance Motor

- Embedded permanent magnets for enhanced efficiency.

- Excellent torque at low speeds and variable loads.

- Widespread in renewable energy and power electronics systems.

High Rotor Pole Switched Reluctance Motor

- Multiple rotor poles for increased torque output.

- Suitable for high-torque, low-speed applications.

- Efficient performance in industrial and EV systems.

Based on Motion Method

The linear, rotary, and axial flux designs of our SRM electric motors provide accurate motion, strong torque, and small size.

Linear Switched Reluctance Motor

- Provides linear motion, no mechanical transmission needed.

- Ideal for precise positioning and smooth movement.

- Used in actuators, conveyors, and robotic systems.

Rotary Switched Reluctance Motor

- Converts electrical energy into rotational motion efficiently.

- Known for high torque density and simple structure.

- Used in pumps, compressors, and electric vehicles.

Featured Products

54WS1-1 Permanent Magnet Brushless Motor

- Drive Voltage: 24V DC

- Rated Speed: 26,000 RPM

- Current: 14.6 A

68WS1 Switched Reluctance BLDC Motor

- Drive Voltage: 220V AC

- Rated Speed: 26,000 RPM, 35,000 RPM

- Current: 2.53 A, 7.1 A

SR Series Switched Reluctance BLDC Motor

- Rated Voltage: 58 V, 220 V

- Rated Speed: 18,000~34,000 RPM

- Phase Configuration: 2 or 3 Phase

Applications

We offer specialized switched reluctance motor control solutions. Explore the primary application areas of our products.

- Electric Vehicle

- Garden Tools

- Industrial Machinery

- Hand Dryer

- Dust Collector

- Wall-breaking Machine

- Robotics

- Pumps and Fans

FAQ

1. Can SRM motors be used in electric vehicles (EVs)?

Yes, SRM motors are well-suited for electric vehicles due to their high torque density, efficiency, and ability to perform well in variable-speed applications, reducing energy consumption in EVs.

2. Is it possible to employ switching reluctance motors in variable-speed drives?

Indeed, SRMs work very well with variable-speed drives. Their efficiency at different speeds, combined with advanced control strategies, makes them ideal for dynamic applications requiring precise speed regulation.

3. Are axial flux switched reluctance motors scalable for different sizes?

Yes, their modular design and flexible construction make them scalable for applications from compact drones to large-scale industrial equipment or high-power electric vehicles.

4. How efficient is a switched reluctance motor?

SRMs are highly efficient, especially in low-speed, high-torque applications. They can achieve efficiency levels of 85-95% when combined with effective controllers and design considerations.

5. Are motors with switching reluctance appropriate for difficult conditions?

Yes, SRMs are known for their robustness and can operate in harsh environments with high temperatures, dust, and vibrations, making them suitable for industrial and off-road applications.

6. How much does a motor with switching reluctance cost?

The cost of an SRM depends on factors such as size, power rating, and complexity of the control system. Generally, SRMs are cost-effective due to their simple construction and minimal parts.