DC Series Motor Manufacturer

LEILI specialize in designing DC series motors offering high torque, smooth speed regulation, and energy efficiency.

We provide tailored solutions to address unique customer requirements, ensuring maximum performance and long-term durability.

- Voltage and Speed Variants

- Custom Coatings

- Overload Protection

- Thermal Rating

By Structure

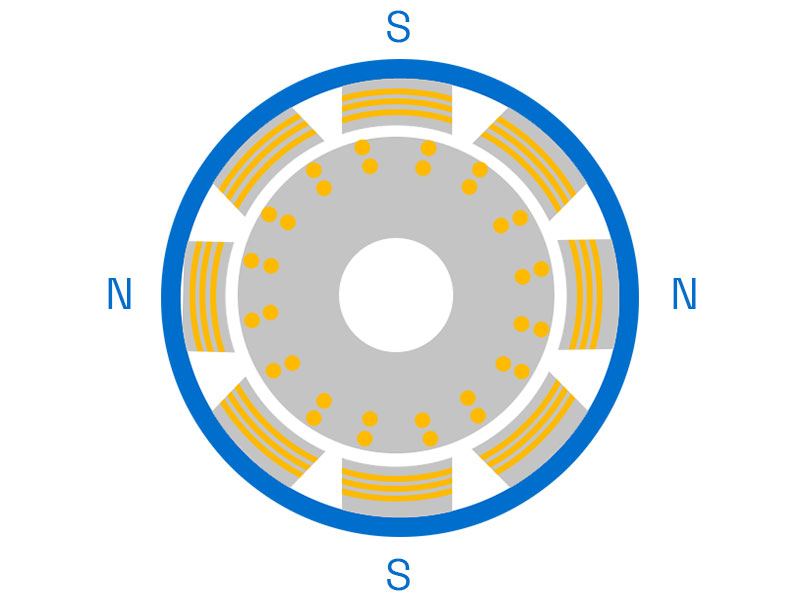

- Stator: Contains field windings to generate a magnetic field.

- Field Windings: Coils and the armature connected in series.

- Rotor (Armature): Rotating part with windings that produce torque.

- Commutator: Reverses current direction in armature windings.

- Brushes: Conduct electricity from the external circuit to armature windings.

- Shaft: Transmits mechanical power from rotor to load.

- Bearings: Support rotor rotation, reducing friction.

- Frame: Encloses and supports motor components.

- Cooling System: Prevents motor overheating, typically through ventilation.

By Wiring Instructions

Armature Connection

- Connect armature leads to the motor terminals.

- Ensure proper insulation and secure connections.

Field Winding Connection

- Connect field windings to the power supply.

- Observe correct polarity to ensure proper field direction.

Grounding

- Ground motor frame to prevent electrical hazards.

- Use appropriate grounding wire for safety.

Switching

- Use suitable switch for voltage and current ratings.

- Ensure switch operates with proper load handling capacity.

Featured Products

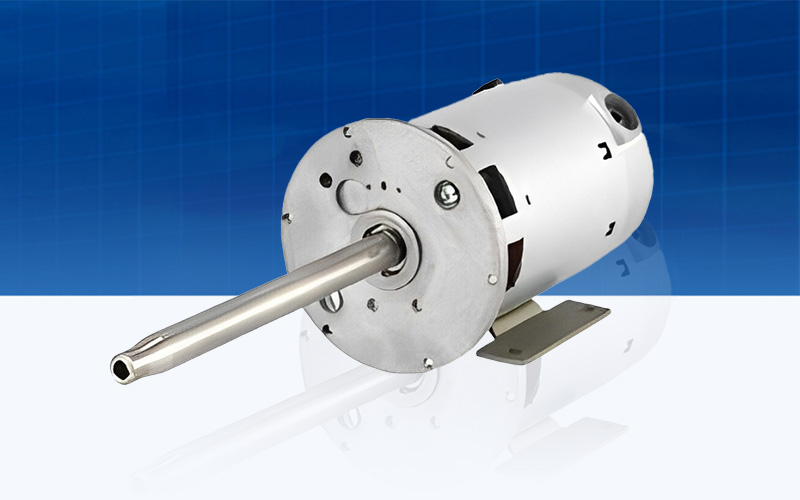

55UJ80 Series Excitation Motor

- No-load Speed: 360±36r/min

- Input Current: <2A

- Load Speed: 180±18r/min

67UJ63 / 87UJ63 Series Excitation Motor

- Rated Voltage: 230V

- No-load Speed: 115-167r/min

- No-load Current: 0.35/0.4A

U9475 Series Excitation Motor

- Rated Voltage: 70V

- No-load Speed: 9600r/min

- No-load Current: 2.4A

U11163 Series Excitation Motor

- Rated Voltage: 120V/230V

- No-load Speed: 21000r/min

- No-load Current:3.5A/7A

Applications

Cranes and Hoists

- DC series motors provide the high starting torque needed for lifting heavy loads, making them ideal for cranes and hoists.

Elevators and Lifts

- Due to their ability to handle high torque at low speeds, DC series motors are used in elevators and lifts for smooth operation and load handling.

Electric Traction

- DC series motors are commonly used in electric trains, trams, and other traction systems where high torque at startup is critical for moving large, heavy loads.

Winches

- Winches used for pulling heavy cables or lifting loads rely on the DC series motor's ability to deliver high initial torque to handle heavy-duty tasks.

Conveyor Belts

- DC series motors are used in conveyor systems because they can handle varying loads and provide the torque needed to start and stop the belt smoothly.

Rolling Mills

- The high starting torque of DC series motors makes them ideal for rolling mills, which require motors that can handle large loads at low speeds.

FAQ

1.Can a DC Series Motor run at a constant speed?

No, its speed is not constant and varies with the load.

2.What is a DC Series Motor's working principle?

The field winding and armature are connected in series, so the same current flows through both, generating a magnetic field.

3.How do DC Series Motors compare to DC Shunt Motors?

DC Series Motors provide higher starting torque, while DC Shunt Motors offer better speed regulation.

4.Are DC Series Motors self-regulating?

Yes, but the speed fluctuates with the load. At no load, the speed can be dangerously high.

5.What types of protection are needed for a DC Series Motor?

Protection devices like overload relays, fuses, or circuit breakers are recommended to protect against excessive current and temperature rise.

6.Can DC Series Motors be used in hazardous environments?

Yes, but they require proper enclosures and protection to prevent damage from dust, moisture, or chemical exposure.