Permanent Magnet Synchronous Motor Manufacturer

We specialize in the production and manufacture of Permanent Magnet Synchronous Motors (PMSM), offering both IPMSM and SPMSM types.

Delivering high efficiency and reliability, we offer customized solutions across industries to ensure peak performance tailored to your unique requirements.

- Rated Voltage: 12V-380V

- Operation Frequency: 50/60Hz

- Rated Speed: 0.028-3000RPM

- Insulation Class: A/E/

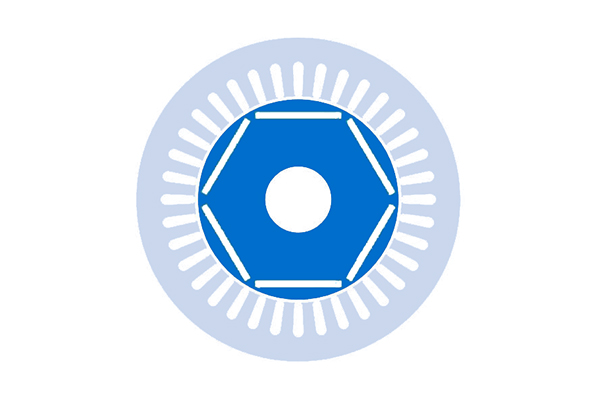

By Structure

Internal Magnets

- In an IPMSM, the permanent magnets are positioned within the interior of the rotor core.

- Offers higher torque density and better performance at high speeds.

- Provides better torque at high speeds and offers superior torque control.

- Can have more effective cooling due to the rotor’s internal structure.

- Preferred for high-performance applications such as vehicles, robotics&machinery.

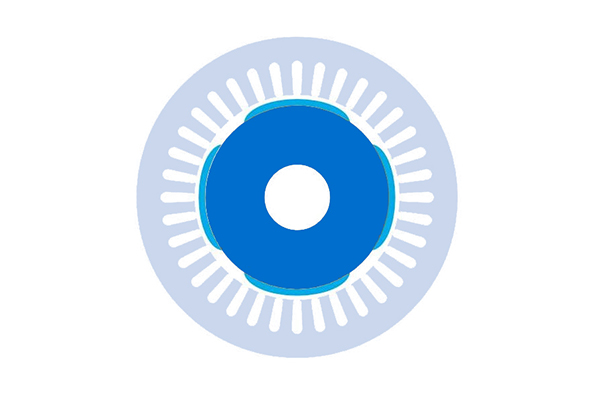

External Magnets

- The permanent magnets of an SPMSM are placed on the rotor's outside.

- Typically more efficient at lower speeds and simpler in design.

- Despite having a greater torque ripple, it delivers good torque at lower speeds.

- Cooling is usually easier due to the simpler rotor design.

- Common in low-cost, low to mid-power applications like appliances, HVAC.

By Current

AC

- AC PMSM operates with alternating current to generate a rotating magnetic field.

- Requires a controller for speed and torque regulation.

- Higher speed and torque control, making it suitable for precise operations.

- Common in high-efficiency applications like industrial machinery and electric vehicles.

DC

- DC PMSM motor uses DC to power the rotor with magnets.

- Generally simpler to control but less efficient than AC versions.

- Requires less complex control systems compared to AC PMSM motors.

- Used in applications requiring constant speed or low power, like small appliances.

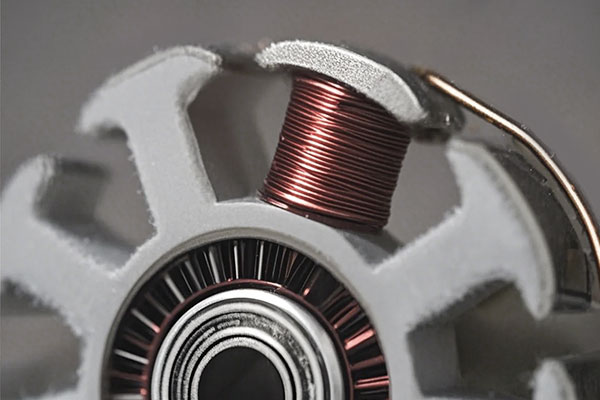

By Winding Configurations

Distributed Winding

- The coils are distributed among several slots around the stator.

- Delivers smoother torque output while minimizing harmonic distortion.

- Typically used in high-performance motors for better efficiency and stability.

Concentrated Winding

- Coils are wound around fewer slots, typically concentrated in one or two slots.

- Offers higher space efficiency and reduced copper losses.

- Can result in higher torque ripple but often used in cost-effective, compact motors.

By Phase

Single

- Single phase PMSM motors are typically used in low-power applications (below 1 kW), offering simple control but limited torque performance.

- They suffer from torque ripple and lower efficiency, with typical efficiency ranging from 70% to 85%.

Three Phase

- 3 phase PMSM motors are the most common, widely used in industrial and automotive fields, supporting power ratings from 100 W to several hundred kW.

- They provide smooth torque output and high efficiency, often achieving 90% to 95% under optimal conditions.

Six Phase

- 6 phase PMSM motors are used in high-reliability or high-power systems like electric ships or heavy-duty EVs, with ratings exceeding 500 kW.

- They offer improved fault tolerance, reduced torque ripple, and better thermal distribution, with efficiencies also reaching 95% or higher.

Featured Products

35SM25 Permanent Magnet Synchronous Motor

- Rated Voltage: 120V/230V

- Operating Frequency: 50/60Hz

- Rated Speed: 0.868-2RPM

35SM30 Permanent Magnet Synchronous Motor

- Rated Voltage: 24V

- Operating Frequency: 50Hz

- Rated Speed: 5.8RPM

0.55KW Permanent Magnet Synchronous Motor

- Rated Voltage: 220V/380V

- Rated Power: 0.55kW

- Rated Speed: 1500/3000RPM

11KW Permanent Magnet Synchronous Motor

- Rated Power: 11kW

- Rated Voltage: 380V

- Rated Torque: 35.02/70.3N·m

Applications

Electric Vehicles (EVs)

- PMSMs provide high torque density and efficiency, making them ideal for main drive motors in electric cars and hybrid vehicles.

CNC Machine

- Used for precision motion control, PMSMs ensure accurate positioning and smooth operation in computer numerical control equipment.

Robotic Arms

- Their fast response and compact design make PMSMs suitable for joint actuators and precision movement in robotics.

Home Appliances

- In air conditioners, washing machines, and refrigerators, PMSMs offer energy-efficient and quiet operation.

Wind Turbines

- PMSMs serve as generators by converting mechanical wind energy into electrical power, offering high reliability and minimal maintenance requirements.

Marine Propulsion

- Employed in electric ships and submarines, PMSMs provide high torque and quiet operation for efficient underwater or onboard propulsion systems.

FAQ

1.How is a PMSM different from an induction motor?

PMSMs use permanent magnets for rotor excitation, eliminating rotor current losses and improving efficiency. Induction motors rely on induced current and tend to have lower efficiency.

2.Are PMSMs suitable for high-speed applications?

Yes, PMSMs can operate at high speeds (up to 30,000 RPM or more), especially when designed with surface-mounted magnets.

3.Do PMSMs require a drive controller?

Yes, PMSMs require a specialized inverter or controller for synchronous operation and field-oriented control (FOC).

4.Are PMSMs more efficient than BLDC motors?

Yes, PMSMs often achieve 90–95% efficiency, and due to sinusoidal back-EMF, they offer smoother and quieter operation than trapezoidal BLDC motors.

5.What’s the typical lifespan of a PMSM?

With proper design and thermal management, PMSMs can last over 20,000 to 30,000 hours or more, depending on usage.

6.Can PMSMs be used in harsh environments?

With proper enclosure and sealing, PMSMs can operate reliably in harsh conditions such as high humidity, dust, or industrial settings.