Permanent Magnet Stepper Motor Manufacturer

Our permanent magnet(PM) stepper motors feature a simple structure, low noise, and adjustable speed driven by magnetic rotor and stator pulse interaction.

We offer flexible customization from gearboxes and lead screws to shaft design and coil resistance to suit diverse applications.

- Voltage Range: 3V to 24V

- Motor Diameter: Available from 6.5mm to 60mm

- Step Angle Options: 7.5°, 9°, 15°, 18°

- Winding Types: Unipolar or Bipolar

- Optional Accessories: Lead screw, Plastic or metal gearbox

- Performance Range: Holding torque from 1.8 to 700 mNm; Speed up to 5500 pulses/second

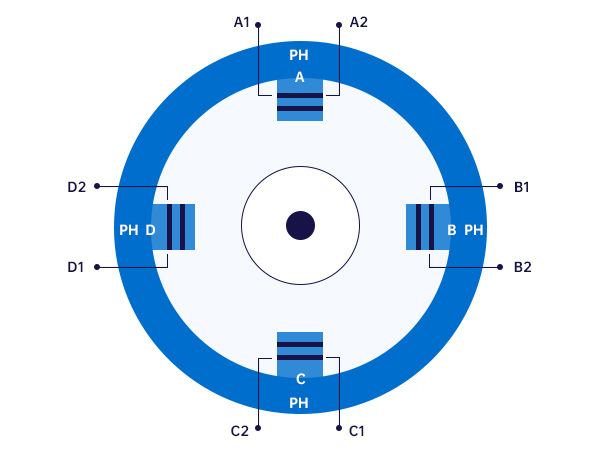

Permanent Magnet Stepper Motor Construction

The stator, rotor, shaft, windings, bearings, and end bells of our permanent magnet stepper motor allow for exact motion.

- Stator: Laminated silicon steel with coils creating magnetic fields to control rotor rotation.

- Rotor: Cylindrical rotor with permanent magnets aligned with stator fields for precise rotation.

- Windings: Insulated copper coils around stator teeth create electromagnetic fields to drive rotor motion.

- End Bells: Metal covers housing bearings, ensuring alignment and support for internal components.

- Bearings: Precision parts minimizing friction, reducing noise and vibration, enhancing motor durability.

- Shaft: Steel rod transmitting rotational torque from internal motor components to external assemblies.

By Design Type

Our permanent magnet stepper motors include geared, claw pole, disc magnet, and can-stack types for diverse precision motion applications.

Geared PM Stepper Motor

- Internal gear improves torque and positional accuracy.

- Compact size suitable for limited installation space.

- Ideal for medical, automation, and precision instrument applications.

Claw Pole PM Stepper Motor

- Claw-shaped stator ensures stable magnetic flux performance.

- Cost-effective design providing medium torque and resolution.

- Used in automotive instruments, HVAC, and office equipment.

Disc Magnet PM Stepper Motor

- Disc magnets deliver rapid response, smooth rotation.

- Low rotor inertia enables fast, precise positioning.

- Ideal for robotics, medical devices, and precision optics.

Can-stack PM Stepper Motor

- Laminated stator enclosed within stacked metal housing.

- Lightweight, economical motor providing moderate torque performance.

- Widely used in printers, cameras, electronics, and appliances.

By Motion Type

The exact linear or rotary motion provided by our permanent magnet stepper motors makes them perfect for small, precise, and energy-efficient automation applications.

Linear PM Stepper Motor

- Built-in lead screw for accurate linear motion in spaces.

- Quiet operation, quick response, repeatable, low heat.

- For medical, robotics, laboratory, and semiconductor equipment.

Rotary PM Stepper Motor

- Precise rotation, stable torque, incremental positioning tasks.

- Compact, robust, energy-efficient, low maintenance.

- Ideal for printers, scanners, office automation, industrial actuators.

By Size

For accurate, space-saving motion control, we provide stable standard sizes and small, micro models of our permanent magnet stepper motors.

Miniature PM Stepper Motor

- Extremely compact in size, typically ranging from 6mm to 20mm in diameter, offering precise positioning and ideal for applications with strict space constraints.

Standard PM Stepper Motor

- Commonly sized from 20mm to 60mm in diameter, providing stable torque output and accurate motion control for industrial automation systems.

Featured Products

25BY412 PM Stepper Motor Linear Actuator Motor

- Voltage: 3.2V

- Step Angle: 7.5°

- Drive Mode: Bipolar

Applications

We offer specialized permanent magnet stepper motor solutions. Explore the key application areas of our products.

- Digital Video Camera

- Security Monitoring

- Printer

- Instrumentation

- Medical Equipment

- Industrial Equipment

- Automobile

- Valve Control

- Bathroom Toilet

FAQ

1.What is the typical step angle in PM stepper motors?

PM stepper motors generally have step angles ranging from 7.5 to 18 degrees per step, depending on the number of rotor poles and stator phases.

2.Can permanent magnet stepper motors be used with microcontrollers?

Yes, PM stepper motors can be easily controlled by microcontrollers via stepper drivers using pulse signals for speed and direction control in embedded applications.

3.Can PM stepper motors be customized for special use?

Yes. Manufacturers can customize shaft dimensions, mounting options, wiring, step angles, and voltages to suit specific mechanical or electrical system requirements.

4.Can PM stepper motors be waterproof or sealed?

Yes. Special housings with IP ratings protect against water, dust, or oil for harsh industrial or outdoor environments.

5.Are PM stepper motors compatible with gearboxes?

Yes. Gearboxes are often added to increase torque and reduce step angle, improving control in high-load or slow-speed applications.

6.How long do PM stepper motors typically last?

With no brushes and minimal wear components, PM stepper motors can last thousands of hours under normal operating conditions with proper cooling and load management.