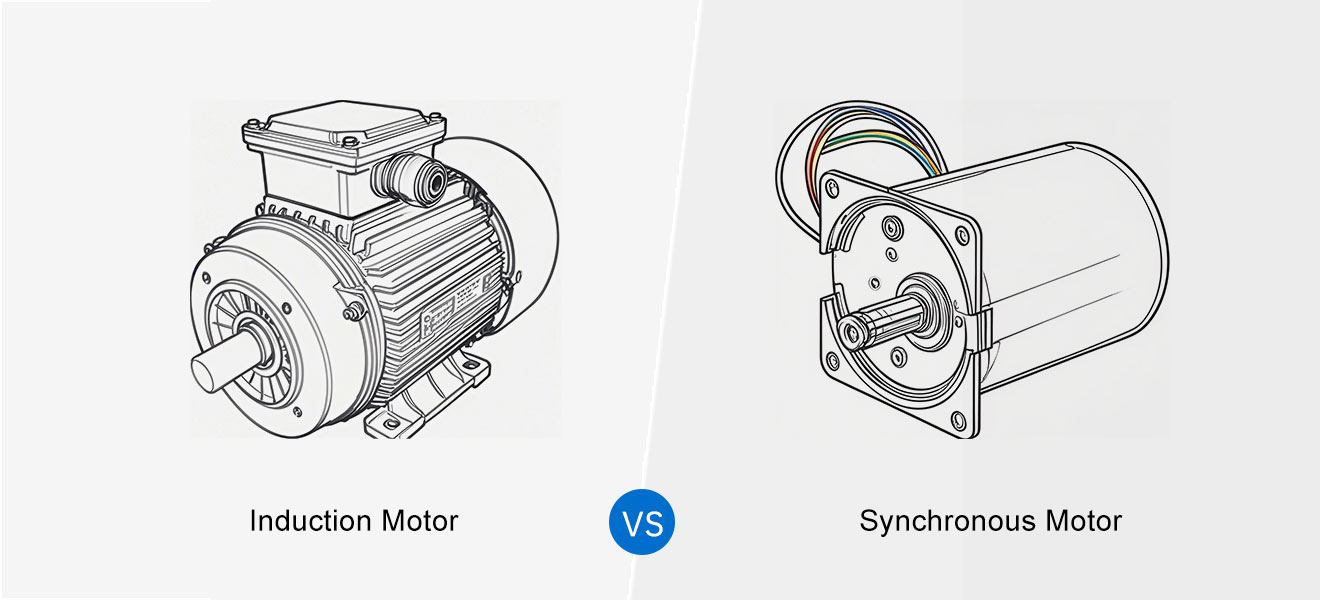

Electric motors are crucial in powering various industrial, commercial, and residential applications. Among the most common types of electric motors are the Induction Motor and Synchronous Motor, each offering unique characteristics suited to different operational needs. Knowing how they differ can assist choose the best motor for a given application, guaranteeing performance, economy, and efficiency.

In this article, we will compare Induction Motors and Synchronous Motors, looking at their working principles, construction, efficiency, speed control, and applications. Additionally, we will present a comparative analysis with charts to highlight the key differences in performance, efficiency, and suitability for different uses.

Overview of Induction Motors and Synchronous Motors

Induction Motor

An Induction Motor (IM) is an asynchronous motor, meaning its rotor does not rotate at synchronous speed. By creating a spinning magnetic field using alternating current (AC) in the stator windings, the induction motor uses electromagnetic induction to create current in the rotor.

The rotor then follows this field, but due to the lag between the magnetic field and rotor movement, the rotor always runs slightly slower than the synchronous speed of the stator field.

Key Features of Induction Motors:

- Simple construction

- Low cost

- Self-starting capability

- Slip between the rotor and stator field

- Variable speed

Synchronous Motor

The synchronous speed, which is the constant speed at which a synchronous motor runs, is set by the supply current frequency and the motor’s number of poles. In a synchronous motor, the rotor and stator’s rotating magnetic fields move at the same speed. This is achieved by using either a DC supply or an excitation system to produce a constant magnetic field in the rotor, synchronizing it with the stator field.

Key Features of Synchronous Motors:

- Operates at constant speed

- Requires an external excitation system for the rotor

- Suitable for power factor adjustment

- Constructed with more complexity than induction motors

- Higher efficiency in certain applications

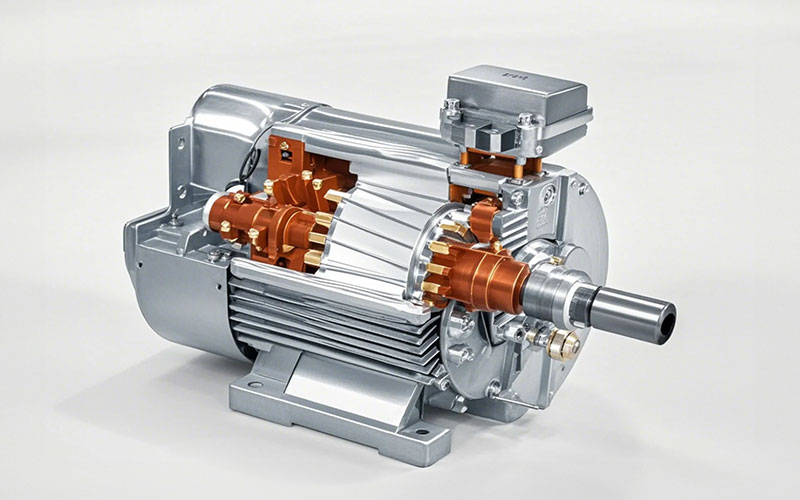

Construction and Working Principles

Induction Motor Construction

Induction motors consist of two main parts:

- Stator: The windings that produce the spinning magnetic field are located in the stationary portion.

- Rotor: The rotating component, often composed of copper bars or laminated iron, moves in tandem with the stator’s generated rotating magnetic field.

Working Principle:

- When an AC voltage is applied, the stator generates a revolving magnetic field, which induces a current in the rotor.

- The rotor rotates as a result of interactions between its magnetic field and the stator’s magnetic field.

- The rotor always lags behind the rotating field, leading to slip, a key characteristic of induction motors.

Synchronous Motor Construction

Synchronous motors are more complex than induction motors, as they require an excitation system to generate the rotor’s magnetic field.

- Stator: The stator has windings that create a revolving magnetic field, just as the induction motor.

- Rotor: The rotor can either be a salient pole rotor (for low-speed applications) or a cylindrical rotor (for high-speed applications). An external source provides a separate DC current that excites the rotor.

Working Principle:

- A revolving magnetic field is produced by the stator.

- The rotor, excited by DC current, creates its magnetic field.

- The rotor is forced to synchronize by the magnetic field of the stator.

- The rotor and stator rotate together at the same speed (synchronous speed), without slip.

Efficiency and Performance

Efficiency of Induction Motors

Induction motors are generally efficient but can suffer from losses due to the slip between the rotor and the stator field. The following variables affect an induction motor’s efficiency:

- Slip: the discrepancy between the synchronous and rotor speeds.

- Load: The efficiency decreases as the load increases, particularly at low load conditions.

- Power factor: Induction motors have a lagging power factor, especially under no-load or light load conditions.

Efficiency of Synchronous Motors

Particularly when running at or close to full load, synchronous motors are typically more efficient than induction motors. Synchronous motors are more efficient since they don’t slide because:

- There are fewer energy losses associated with the rotor.

- It is possible to perform power factor adjustment, which lowers the system’s reactive power requirement.

- Applications requiring great efficiency and steady speed frequently employ synchronous motors.

Performance Comparison Chart

| Parameter | Induction Motor | Synchronous Motor |

| Speed | Variable, with slip | Constant speed, no slip |

| Efficiency | Moderate, decreases with load | High, especially at full load |

| Power Factor | Lagging requires compensation | Can improve power factor |

| Starting Mechanism | Self-starting | Requires external excitation |

| Complexity | Simple | More complex with additional components |

| Cost | Lower | Higher |

Speed Control

Induction Motor Speed Control

Induction motors have variable speeds, but controlling the speed can be complex. Common methods for controlling the speed of induction motors include:

- V/f Control: The most common method, is adjusting the voltage and frequency simultaneously.

- Rotor Resistance Control: lowering speed by raising the rotor circuit’s resistance.

- Pole Changing: To change the motor’s speed, adjust the number of poles.

- Variable Frequency Drive (VFD): By altering the supply frequency, VFDs are frequently utilized to regulate the speed of induction motors.

Synchronous Motor Speed Control

Synchronous motors depend on the frequency of the supply to run at a set speed. Speed control is not as simple as in induction motors. However, speed can be adjusted in specific applications using:

- Changing supply frequency: To change the synchronous speed.

- Excitation control: Modifying the rotor’s excitation system can affect the motor’s load-carrying capability but does not impact speed directly.

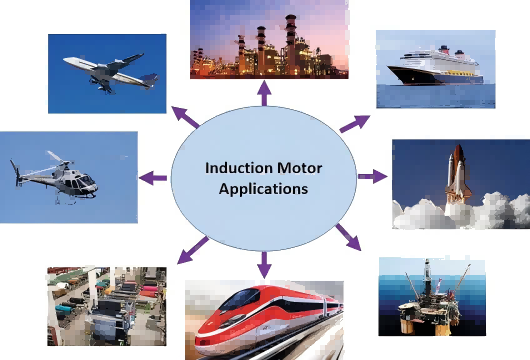

Applications

Applications of Induction Motors

Due to their versatility, induction motors are frequently utilized in:

- Pumps, fans, and compressors are examples of industrial drives.

- HVAC systems: For ventilation and air conditioning

- Household appliances: Washing machines, refrigerators

- Agriculture: Irrigation pumps, feed conveyors

- Transportation: Electric vehicles (in some cases)

Applications of Synchronous Motors

Synchronous motors are used in specialized applications where constant speed, efficiency, and power factor correction are needed:

- Large power generation: Synchronous motors are commonly used in power plants.

- Power factor correction: used to increase power factor in sectors with high inductive loads.

- High-performance drives: Used in industries where precise speed control is required, such as paper mills, textile industries, and steel plants.

- Synchronous condensers: To improve voltage stability in power grids.

Cost Comparison

Induction motors are generally more affordable due to their simpler construction and self-starting mechanism. Because of their low maintenance needs and robust design, they are an affordable option for a range of applications.

Synchronous motors are more expensive, mainly due to their complex construction, external excitation system, and additional components. However, the increased efficiency and power factor correction benefits make them more economical in large-scale or energy-intensive applications.

Advantages and Disadvantages

Advantages of Induction Motor

- Simple construction and reliable operation.

- Cost-effective for a wide range of applications.

- Self-starting capability.

- Less upkeep because there are no brushes.

Disadvantages of Induction Motors

- Lower efficiency compared to synchronous motors, especially at light load.

- Variable speed, requiring additional equipment for precise speed control.

- Power factor correction devices may be necessary for lagging power factors.

Advantages of Synchronous Motors

- Constant speed operation makes it perfect for applications that need a lot of precision.

- High effectiveness, particularly when loaded.

- Reactive power is decreased via power factor correction capabilities.

- No slip, which contributes to lower energy losses.

Disadvantages of Synchronous Motors

- Complex construction requires more components and maintenance.

- Requires the rotor to be excited externally.

- More expensive initially than induction motors.

- Not self-starting, requiring external mechanisms for starting.

Conclusion

Induction motors offer simplicity, reliability, and lower cost, making them suitable for a broad range of applications. On the other hand, synchronous motors provide higher efficiency, constant speed, and power factor correction, making them ideal for high-performance and energy-intensive applications.

Engineers and companies can choose the best motor type for their requirements by being aware of the variations in construction, performance, efficiency, and applications. By considering factors such as load, speed control requirements, power factor, and cost, one can make an informed decision on whether an induction motor or a synchronous motor is the better choice for a given task.