Hybrid Stepper Motor Manufacturer

We offer custom hybrid(HB) stepper motors with a wide selection of frame sizes, shaft types, and winding options to suit diverse application needs.

These motors provide high speed, torque, and ultra-precise control for accurate starting, stopping, and positioning, ensuring reliable performance and seamless integration into motion systems.

- Stepper Angle: 0.45°,0.9°, 1.8°

- Dimension Diameter: 20mm~86mm

- Phase Configuration: 2 phase, 3 phase

- Winding Configuration: Unipolar, Bipolar

- Motion Frequency: Reaches up to 4500 pulses per second

- Special Features: IP65, anti-corrosion, low vibration & noise

Hybrid Stepper Motor Construction

A hybrid stepper motor generally consists of 6 parts: stator, rotor, shaft, bearings, housing, and end caps—ensuring precise, stable, and efficient performance.

- Stator: Laminated steel core with toothed poles and copper windings, producing rotating magnetic fields to drive the rotor step by step.

- Rotor: Composed of toothed iron caps and a permanent magnet, ensuring strong magnetic coupling, precise steps, and improved holding torque.

- Shaft: Central rod connected to the rotor, transmitting rotational motion to external mechanisms with stability and minimal mechanical loss.

- Bearings: High-precision ball bearings support the shaft, reducing friction and enabling smooth, low-noise rotation during motor operation.

- Housing: Protective outer casing encloses all internal parts, maintains motor structure, and helps dissipate heat generated during operation.

- End Caps: Mounted at both ends, they secure internal components and align the shaft with integrated bearing supports.

General Types

Our hybrid stepper motor types include open-loop synchronous and closed-loop servo models, balancing cost-efficiency, accuracy, and performance across varied motion applications.

Hybrid Synchronous Stepper Motor

- An open-loop system moves by input pulse signals.

- No feedback, affordable, and easy to use.

- Best for printers, plotters, and 3D machines.

Hybrid Servo Stepper Motor

- Closed-loop with encoder for real-time correction.

- Prevents step loss, improves torque and speed.

- Ideal for robotics, automation, and dynamic loads.

Common Equipped Options

For improved performance and precise control, hybrid stepper motors come with choices including lead screw, integrated driver, gearbox, hollow shaft, encoder and brake.

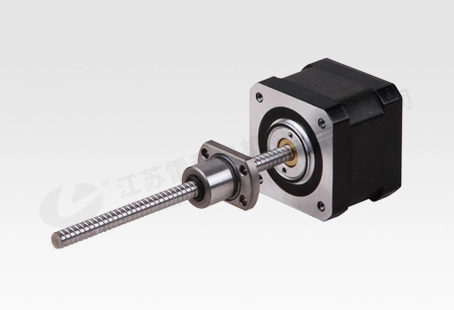

Lead Screw

- Converts rotation to linear motion with slide screw.

- Ball screw improves efficiency, accuracy over slide screw.

- Used in CNC, 3D printers, and actuators.

Integrated Driver / Controller

- Combines motor, driver, controller into one unit.

- Reduces wiring, great for compact control setups.

- Simplifies robotics and automation integration.

Gearbox / Gearhead

- Reduces speed, increases torque for heavy loads.

- Enhances control in applications requiring high torque.

- Used in conveyors, robots, and packing equipment.

Hollow Shaft

- Allows cable routing or fluid through motor center.

- Enables compact use in rotary tables or slip rings.

- Ideal for automation, medical, and rotary actuators.

Encoder

- Sends motor position, speed&direction feedback.

- Enables closed-loop control and prevents step loss.

- Critical for robotics, inspection, and automation systems.

Brake

- Holds shaft position when power is off.

- Stops back-driving on vertical or sloped loads.

- Used in lifts, Z-axes, and safety systems.

Featured Products

14 Series Ball Screw Hybrid Stepper Motor

- Voltage: 6.6V

- Ball Size: Ø0.8

- Shaft Root Dia: Ø3.3

28 Series Hybrid Stepper Motor

- Voltage: 24V

- Drive Mode: Constant current

- Phase Configuration: 2 phase

57 Series Hybrid Stepper Motor

- Voltage: 48V

- Drive Mode: Constant current

- Phase Configuration: 2 phase

Hybrid Stepper Motor Applications

Hybrid type stepper motor applications span automation, robotics, surveillance, and consumer devices, offering compact size, precise control, and quiet, reliable motion performance.

Medical Appliance

- Used in diagnostic devices, infusion systems, and imaging equipment that demand compact size, quiet operation, and precise motion control under strict conditions.

Industrial Equipment

- Drives automation machinery, robotic arms, and material handling systems requiring high torque, accurate movement, and long-term reliability in challenging environment.

CCTV Monitor

- Controls pan, tilt, and zoom mechanisms to deliver smooth, accurate camera positioning and reliable operation for effective video surveillance applications.

OA Financial Equipment

- Operates printers, ATMs, and banking machines where quiet movement, space-saving design, and consistent positioning are critical to smooth transaction performance.

Auto Parts

- Used in throttle control, headlight adjustment, and HVAC systems requiring responsive, compact motion under variable automotive conditions.

Home Appliance

- Powers devices like washing machines, air purifiers, and smart curtains need precise positioning and smooth operation with minimal noise.

FAQ

1.Can gearboxes be integrated with Hybrid Stepper Motors?

Yes, Hybrid Stepper Motors can be paired with planetary or spur gearboxes to increase torque, reduce speed, and enhance mechanical advantage in precision motion control systems.

2.Can Hybrid Stepper Motors be customized for applications?

Yes, Hybrid Stepper Motors can be customized by modifying flange size, shaft type, step angle, wiring configuration, and voltage specifications to match unique project or equipment requirements.

3.What insulation class is used in Hybrid Stepper Motor windings?

Hybrid Stepper Motors typically use Class B or Class F insulation for windings, allowing safe operation in environments with temperatures up to 130°C or 155°C, respectively.

4.Are Hybrid Stepper Motors resistant to moisture or dust?

Hybrid Stepper Motors can be designed with sealed housings, coated windings, and IP-rated enclosures to protect against moisture, dust, and other harsh environmental conditions.

5.What testing is done during Hybrid Stepper Motor manufacturing?

Hybrid Stepper Motors undergo torque, resistance, insulation, step accuracy, vibration, and dielectric strength tests to ensure performance consistency, reliability, and compliance with industry standards.

6.What standards apply to Hybrid Stepper Motor production?

Hybrid Stepper Motor production often complies with ISO 9001, CE, and RoHS standards, ensuring consistent quality, environmental safety, and compatibility with global industrial systems.