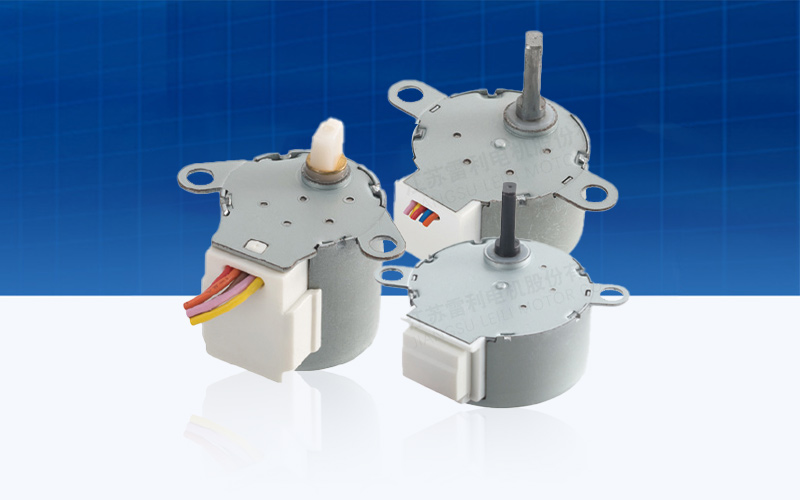

Geared Stepper Motor Manufacturer

Our Geared Stepper Motors, available in micro and small sizes, offer low noise, accurate positioning, and fine-step control.

With metal or plastic gearboxes, we provide customized solutions tailored to low-speed, high-torque applications.

- Gearbox Types: Worm, Planetary, Helical, Spur

- Rated Voltage: 5V, 12V, 24V

- Step Angle: 3.75°, 5.625°, 7.5°, 11.25°

- Diameter Range: 20mm~50mm

- Maximum Torque: Greater than 500 mNm

Geared Stepper Motor Types We Can Provide

We provide four types of geared stepper motors, offering high torque, precise control, quiet operation, and durability for various industrial applications.

Worm Gear Stepper Motor

- Single-threaded worm gear for high torque output.

- Compact design ideal for limited space applications.

- Self-locking feature for stable and secure positioning.

Planetary Gear Stepper Motor

- Multiple planetary gears for smooth, efficient operation.

- Low backlash design for high precision control.

- Durable structure offers high torque and reliability.

Helical Gear Stepper Motor

- Angled teeth reduce noise for quieter operation.

- High load capacity for demanding applications.

- Efficient design minimizes friction and wear.

Spur Gear Stepper Motor

- Parallel teeth design ensures straightforward operation.

- Ideal for high-speed, low-load applications.

- Cost-effective and reliable for various uses.

Polarity Options

The unipolar and bipolar versions of our geared stepper motors offer versatility for a range of applications.

Unipolar

- Geared unipolar stepper motors have center-tapped windings, which restrict the direction of current flow via each coil half.

- Ideal for applications prioritizing simplicity and low cost, this design offers straightforward and easy control.

Bipolar

- Geared bipolar stepper motors use the complete winding, allowing current to travel both ways.

- Because bipolar motors are known to provide more torque and efficiency than unipolar motors, they are perfect for applications that need great performance and precise control.

Available Accessories

Our stepper gear motor accessories include encoders for precise control and motor drivers for seamless integration, ensuring smooth operation and optimal performance in automated systems.

Encoder

- This motor integrates an encoder to provide feedback on position and speed, ensuring precise control and higher accuracy in applications requiring closed-loop systems and real-time monitoring.

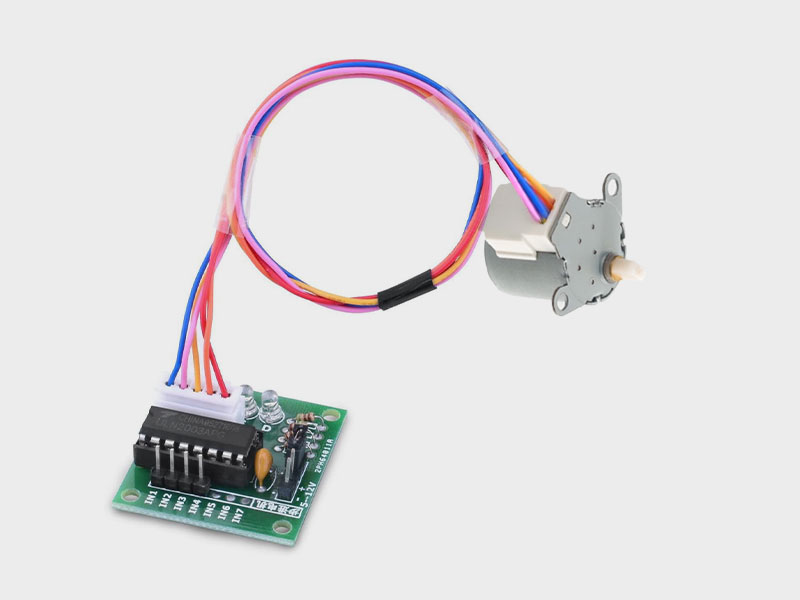

Motor Driver

- Equipped with a driver, this motor enables easy integration and smooth operation by controlling current and voltage, optimizing performance for various automated systems, and reducing installation complexity.

Featured Products

Geared Stepper Motor Applications

For accurate control, our geared stepper motors are utilized in electronic instruments, door locks, CCTV monitors, refrigerators, air conditioners, and intelligent sanitary systems.

Air-conditioning

- Used to control airflow direction, optimize temperature regulation, and enhance cooling efficiency for improved comfort and energy savings.

Refrigerator

- Powers fan speed and compressor adjustments, ensuring energy-efficient cooling and maintaining optimal temperature levels for food preservation.

Intelligent Sanitary

- Drives automated systems like faucets and toilet lids, offering precise motion control for convenience, hygiene, and improved user experience.

Automatic Door Lock

- Enables secure, precise locking and unlocking mechanisms, enhancing safety and providing convenience in both residential and commercial settings.

CCTV Monitor

- Facilitates smooth pan and tilt functions for cameras, ensuring adjustable movement and extensive surveillance coverage in security systems.

Electronic Instruments

- Provides precision for movements in devices like printers, scanners, and measuring instruments, ensuring accuracy and reliable operation.

FAQ

1. Are your gearboxes modular or interchangeable?

Yes, many of our gearboxes are modular and can be interchanged across compatible motor sizes, helping reduce inventory complexity and support flexible integration.

2. What gear ratios do you offer for geared stepper motors?

Our gear ratios range from 3:1 to 100:1, with custom ratios available to meet precise torque and speed output requirements in your specific motion control application.

3. Do you offer technical integration support?

Yes, we provide datasheets, wiring guides, CAD files, and expert support to assist customers in system integration.

4. Can you customize a right-angle stepper motor?

Yes, right-angle stepper motors can be customized for flange type, shaft length, voltage, wiring configuration, gear ratio, and mounting orientation to meet your specific requirements.

5. Are your geared stepper motors compliant with international standards?

Yes, our motors comply with CE and RoHS certifications, and we can support additional compliance such as UL or REACH depending on your project needs.

6. How long is the production cycle for geared stepper motors?

Depending on the complexity of the product and the amount of the order, lead times normally vary from 15 to 30 working days.