In the world of precision motion control, stepper motors offer a unique blend of simplicity and accuracy. However, a key factor in determining performance is how they are motivated.

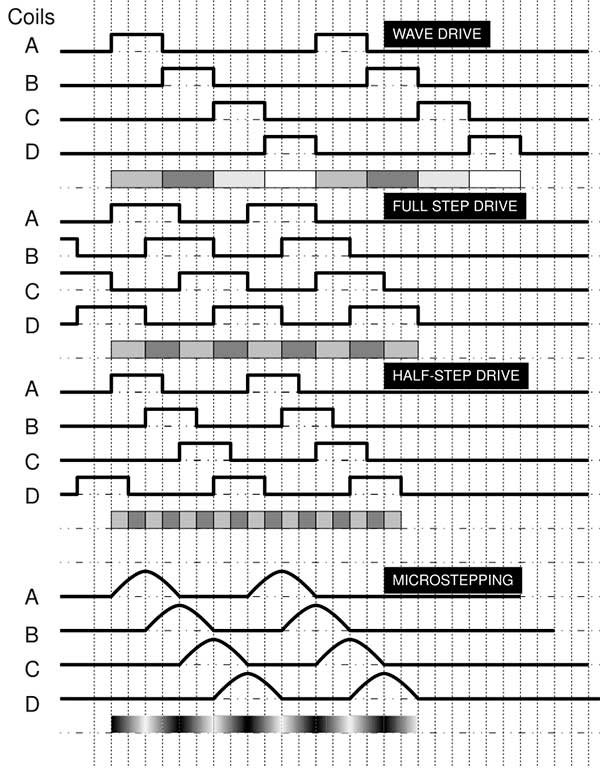

Four common stepper motor drive techniques—Full-step Drive, Half-step Drive, Wave Drive, and Microstepping—are examined and contrasted in this article. Whether you’re designing a CNC machine, automating a 3D printer, or building a robotic arm, understanding these drive modes is essential.

Understanding the Basics of Stepper Motors

Stepper motors are electro-mechanical systems that translate electrical pulse signals into precise, incremental mechanical motion. They rotate in precise, fixed angular steps, making them ideal for applications requiring accurate positioning without feedback systems.

Each stepper motor consists of a rotor (usually permanent magnet or variable reluctance type) and a stator with multiple windings or coils. The way these coils are energized defines the motor’s step resolution, torque output, smoothness of motion, and efficiency.

Let’s delve into the four main drive techniques that influence the performance of a stepper motor.

Full-step Drive

In full-step drive mode, the motor moves one full step for each electrical input pulse. Two coils are energized simultaneously, producing maximum torque and advancing the rotor by one complete step (e.g., 1.8° per step for a typical 200-step motor).

| Pros | Cons |

| Simple to implement | Generates vibration and noise at low speeds |

| Produces maximum holding torque | Limited resolution (200 steps/rev) |

| Reliable and predictable motion | Motion is not very smooth |

Applications:

- Industrial printers

- Linear actuators

- CNC routers requiring simple, robust motion

Half-step Drive

Half-step drive alternates between one coil and two coils being energized. This effectively doubles the number of positions per revolution (e.g., from 200 to 400 steps/rev in a 1.8° motor), improving resolution and reducing resonance.

| Pros | Cons |

| Higher resolution than full-step mode | Uneven torque between full and half steps |

| Smoother rotation and reduced vibration | Slightly more complex driver circuitry |

| Balanced compromise between torque and smoothness | Lower torque than full-step in some phases |

Applications:

- 3D printers

- Medical devices

- Surveillance cameras

Wave Drive (One-phase-on Driving)

Wave drive, or single-coil excitation, energizes one winding at a time. The rotor advances step-by-step as each coil is sequentially powered, creating the magnetic field necessary for movement.

| Pros | Cons |

| Simplest control scheme | Produces the lowest torque of all drive methods |

| Low power consumption | Inefficient use of motor windings |

| Minimal hardware requirements | Rough and noisy motion; easily loses steps under load |

Applications:

- Battery-powered equipment

- Lightweight automation

- Simple DIY robotics

Microstepping

Microstepping involves breaking each full step into many smaller steps—often 4, 8, 16, 32, or even 256 microsteps. This is accomplished by supplying the coils with sinusoidal or pseudo-sinusoidal current waveforms. The result is ultra-smooth motion, finer resolution, and quieter operation.

| Pros | Cons |

| Ultra-smooth motion | Torque per microstep is significantly lower |

| Highest positional resolution | Requires complex and expensive drivers |

| Extremely quiet operation | May suffer from missed steps at very high resolutions |

Applications:

- Professional 3D printers

- High-end CNC machines

- Scientific instrumentation

- Medical-grade automation

Technical Comparison Table

| Drive Method | Full-step | Half-step | Wave Drive | Microstepping |

| Step Angle (Typical) | 1.8° | 0.9° | 1.8° | 0.007°–1.8° |

| Torque | High | Medium-High | Low | Low per step |

| Smoothness | Medium | Medium | Low | Very High |

| Resolution | 200 steps/rev | 400 steps/rev | 200 steps/rev | 1600–25600 steps/rev |

| Complexity | Low | Medium | Very Low | High |

| Power Use | High | Medium | Low | Medium |

| Best Suited For | CNC, Printers, Robotics | 3D Printers, Cameras | Basic Automation, DIY Electronics | Precision Motion Systems |

Torque Considerations

Torque is a critical factor in motor selection. Here’s how these drive methods compare in terms of torque:

- Full-step (2-phase on) delivers the highest torque.

- Half-step delivers slightly less, with variations in torque depending on whether one or two phases are energized.

- Wave drive provides the lowest torque, only about 70% of full-step mode.

- Microstepping sees a drop in torque per microstep but maintains smooth, continuous motion.

Also, microstepping’s torque is more linear with respect to speed, which is beneficial in high-precision applications.

Noise and Vibration

Noise and vibration become especially important in applications like robotics, medical devices, and audio-sensitive environments.

- Wave drive and full-step generate the most vibration and noise due to abrupt changes in magnetic fields.

- Half-step offers a balance but still shows some mechanical ripple.

- Microstepping excels with virtually silent operation and the smoothest motion.

Engineers often favor microstepping in applications requiring stealthy or fluid movement.

Control Complexity and Cost

Cost and control complexity increase significantly from wave drive to microstepping:

- Wave drive: Simple hardware, suitable for minimal-control systems.

- Full-step and half-step: Simple, moderate control logic that is most frequently utilized.

- Microstepping: Requires high-resolution DACs, current feedback systems, and microcontroller processing, making it the most expensive and complex to implement.

However, this cost pays off in environments demanding smooth performance and high resolution.

Energy Efficiency

Efficiency depends on both power consumption and performance per watt:

- Wave drive is the most power-efficient but suffers in torque.

- Full-step uses the most energy but provides maximum mechanical work.

- Microstepping, with optimized drivers, can be surprisingly efficient despite complexity, especially when properly tuned for application demands.

When running at partial load or lower speeds, microstepping may even consume less energy overall while offering better control.

Advanced Use Cases and Integration

With the emergence of IoT and Industry 4.0, stepper motors are increasingly integrated into smart systems:

- Microstepping motors are found in high-resolution robotics, lab automation, camera gimbals, and semiconductor handling equipment.

- Half-step and full-step drive methods dominate in classic automation systems, pick-and-place machines, and desktop CNC routers.

- Wave drive still finds niche use in toys, low-cost gadgets, and educational platforms.

Hybrid Stepping Modes

Many real-world applications combine multiple drive methods to balance cost, complexity, and performance. For example:

- A system may use full-step mode during high-torque acceleration phases and switch to microstepping during final positioning to improve precision.

- Closed-loop stepper drivers also combine encoder feedback with microstepping for precise yet energy-efficient motion.

This dynamic switching can optimize the motor’s full potential.

Future Trends

As microcontrollers become more powerful and cost-effective, microstepping is becoming the standard, even for budget devices. Future innovations may include AI-assisted current modulation for stepper motors, sensorless feedback systems, and more compact integrated driver ICs that reduce board space while offering full programmable control.