Behind the smooth operation of a washing machine lies an intricate system of components working together to ensure that water is drained efficiently. Among these components, the drain motor plays a pivotal role in expelling water from the machine after the wash and rinse cycles. But not every drain motor is created equal. Various types of drain motors are used in washing machines, and understanding the differences between them can help consumers and repair technicians alike make better decisions regarding repairs or replacements.

We will also compare the efficiency, longevity, and reliability of each type to help users determine which drain motor is best suited for their needs.

What is a Drain Motor?

One essential part of a washing machine is the drain motor, which removes water from the drum at the end of the washing or rinsing cycles. The drain motor is directly linked to the drain pump, and together they work to expel water through the drain hose into your home’s plumbing system.

Drain motors come in a variety of forms, including:

- Universal Motors

- Permanent Magnet Motors (PMM)

- Induction Motors

- Brushless DC Motors (BLDC)

- Step Motors

Each type of motor has its specific advantages and drawbacks, and the selection of a motor depends on factors like power efficiency, cost, longevity, and the design of the washing machine.

Types of Drain Motors in Washing Machines

Universal Motors

Due to its great speed and versatility, universal motors are frequently seen in washing machines. Since they can operate on both AC and DC power, they are referred to as “universal.”

Working Mechanism:

To guarantee that the motor rotates continuously, universal motors use brushes and a commutator to change the direction of the current. The brushes wear out over time, which can lead to maintenance issues, but these motors provide high torque and speed.

Advantages:

- High-speed operation: These motors can achieve a high rotational speed, making them ideal for applications where speed is essential, such as draining water quickly.

- Compact size: Universal motors are smaller in size compared to other types of motors, which helps save space in washing machine designs.

- Inexpensive: These motors are relatively affordable to manufacture and replace.

Disadvantages:

- Wear and tear: Over time, the commutator’s brushes and other components deteriorate and need to be replaced or maintained.

- Less energy-efficient: Universal motors are not as energy-efficient as other motor types, especially when used for extended periods.

- Noise: Because of the friction between the commutator and brushes, these motors typically make more noise.

Permanent Magnet Motors (PMM)

Washing machines are increasingly using permanent magnet motors (PMMs) because of their low maintenance needs and high efficiency.

Working Mechanism:

PMMs use permanent magnets to generate a magnetic field. The rotor (the part that rotates) is driven by the magnetic field created by the stator, which is powered by an external electrical current. This design lowers maintenance by doing away with the requirement for brushes and a commutator.

Advantages:

- High efficiency: PMMs are highly efficient and consume less power compared to universal motors.

- Quiet operation: With fewer moving parts, PMMs tend to operate more quietly.

- Low maintenance: Because these motors don’t have brushes or commutators, they need less upkeep.

- Compact design: PMMs are smaller and lighter than universal motors, which makes them suitable for more compact washing machines.

Disadvantages:

- Higher initial cost: PMMs are generally more expensive to produce than universal motors.

- Limited torque at low speeds: These motors may struggle to generate enough torque at low speeds, which could affect their performance during the draining cycle.

Induction Motors

Induction motors are widely used in industrial applications and are also found in certain washing machines. These motors provide rotating motion by electromagnetic induction.

Working Mechanism:

The rotor of an induction motor rotates as a result of a current being induced by a revolving magnetic field created in the stator. These motors are powered by alternating current (AC), and the rotor does not require direct electrical contact, unlike universal motors.

Advantages:

- Highly durable: Induction motors have fewer moving parts and are designed to last for many years without significant wear and tear.

- Energy-efficient: These motors are efficient and use less energy compared to universal motors.

- Smooth operation: Induction motors operate smoothly with minimal noise and vibration.

Disadvantages:

- Slower acceleration: Induction motors take longer to accelerate and may not be as effective at providing rapid draining compared to other types.

- Higher cost: Induction motors can be more expensive to produce, which may increase the overall cost of the washing machine.

- Size: These motors tend to be larger and heavier than PMMs and universal motors.

Brushless DC Motors (BLDC)

Brushless DC motors (BLDC) are increasingly becoming the go-to solution for modern washing machines due to their energy efficiency and quiet operation.

Working Mechanism:

An electronically controlled stator and a permanent magnet rotor are used in BLDC motors. Because BLDC motors don’t use brushes like conventional DC motors do, they require less maintenance and are more efficient.

Advantages:

- Energy efficiency: Because of their exceptional performance and low power consumption, BLDC motors are incredibly energy-efficient.

- Quiet operation: These motors are quieter than universal motors and induction motors, which is important in household appliances.

- Long lifespan: BLDC motors last longer than many other kinds of motors since there are no brushes to wear out.

Disadvantages:

- High cost: The initial cost of BLDC motors is relatively high, which could increase the price of washing machines.

- Complexity: The electronics required to control the motor can add complexity and cost to the washing machine.

Step Motors

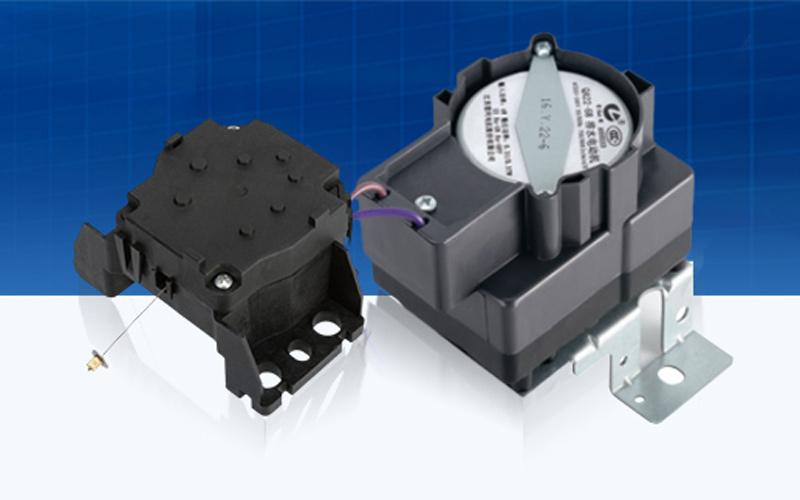

Step motors are not as commonly used in washing machines as the other types of motors, but they are gaining popularity due to their precision and control in certain applications.

Working Mechanism:

Step motors operate by dividing a full rotation into discrete steps, allowing the motor to move in precise increments. These motors are controlled by a series of electrical pulses that cause the rotor to move step by step.

Advantages:

- Precision: Step motors provide excellent precision, which can be beneficial for specific washing machine tasks such as precise water drainage.

- Reliability: These motors are reliable and require minimal maintenance.

- High torque: Step motors can generate high torque even at low speeds.

Disadvantages:

- Power consumption: Compared to other motor types, step motors often use more power.

- Complex control: The control circuitry for step motors is more complex than other motor types, which can increase the cost of the washing machine.

Comparison of Different Drain Motors

| Feature | Universal Motor | Permanent Magnet Motor (PMM) | Induction Motor | Brushless DC Motor (BLDC) | Step Motor |

| Speed | High speed | Moderate speed | Low to moderate speed | High speed | Moderate speed |

| Efficiency | Low | High | High | Very high | Moderate |

| Cost | Low | Moderate | High | High | High |

| Noise | High | Low | Low | Very low | Moderate |

| Maintenance | High (due to brushes) | Low | Low | Very low | Moderate |

| Lifespan | Short | Long | Very long | Long | Long |

| Torque | High | Moderate | Moderate | High | High |

| Application | Common in budget machines | Premium models, compact designs | Industrial, durable models | High-end, energy-efficient models | High-precision tasks |

Conclusion

Universal motors are popular in budget machines but tend to be noisy and less efficient. Permanent magnet motors are more expensive yet provide a balance between quiet operation and efficiency. Induction motors are durable and energy-efficient but may not be suitable for all washing machine designs due to their size. Although they are less common and can be more costly to maintain, step motors provide exceptional precision.

Ultimately, the choice of motor depends on factors such as budget, desired features, and the specific needs of the user. For those looking for high performance and long-term reliability, permanent magnet motors and brushless DC motors are great options. However, for consumers looking for affordable alternatives, universal motors still have a place in the market.