DC Brush Gear Motor Manufacturer

LEILI produce and customize brushed DC gear motors with various voltages, gear ratios, and torque levels.

Our motors deliver stable performance, compact size, and high efficiency with tailored solutions for precise speed and torque integration in applications.

- High Torque Output with Compact Size

- Metal and Plastic Gearbox Options

- Spur Gear, Planetary Gear, Worm Gear Options

- H Insulation Class

By Motor Shape

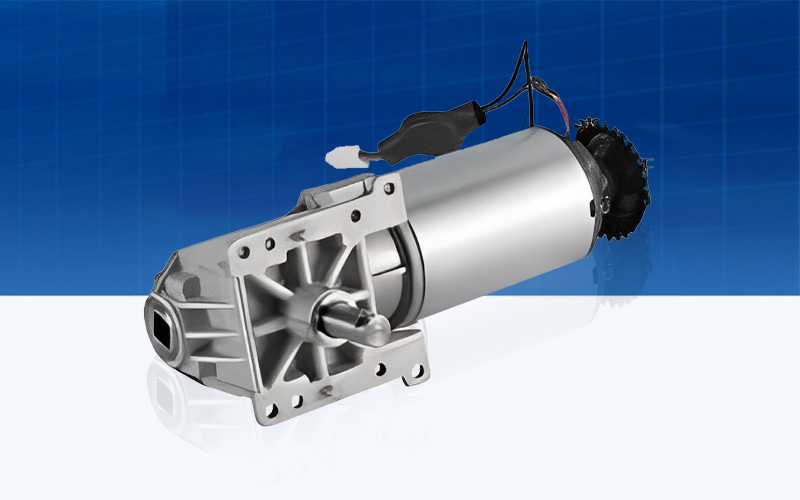

Square Gear DC Brush Motor

- Flat surfaces make it easy to mount on flat panels or frames.

- Internals can include spur gears or sometimes planetary gears.

- Ideal for smart locks, toys, and consumer electronics.

Cylindrical Gear DC Brush Motor

- Often compact and lightweight.

- Round shape for easy installation into round housings or tight spaces.

- Common in toys, electronics, home appliances, automation tools.

By Gear Type

Spur Gear DC Brush Motor

- Uses simple straight-cut gears.

- Cost-effective and efficient.

- Common in toys, vending machines, and small appliances.

Planetary Gear DC Brush Motor

- Uses planetary gear sets (sun, planet, ring).

- Offers higher torque, compact size, and better durability.

- Used in robotics, industrial drives&automation.

Worm Gear DC Brush Motor

- Uses a worm screw and gear.

- Provides high torque, low speed, and self-locking ability.

- Used in lifts, gates, and medical equipment.

By Gear Material

Metal

- Metal gear motors have high strength and durability.

- Handles higher torque loads.

- Longer lifespan under continuous or heavy-duty use.

- Better resistance to wear and heat.

Plastic

- Plastic gears wear faster under load.

- More affordable and lightweight.

- Quieter operation due to softer gear contact.

- Suitable for low to moderate torque applications.

By Shaft Type

Single Shaft

- Most common type.

- One output shaft on one end of the motor.

- Ideal for general applications where you only need to drive one mechanism.

Dual Shaft

- Has two output shafts: one on each end of the motor.

- Adding an encoder to one shaft for feedback control.

- Driving two mechanisms simultaneously.

- Balancing or symmetrical mechanical designs.

Combination Options

With Encoder

- Provides feedback on speed and position.

- Use Case: Ideal for closed-loop control, robotics, and automation.

- Benefit: Enables precise motion control and positioning.

- Usually has a rear-mounted rotary encoder (optical or magnetic).

With Wheel

- Motor pre-attached to a wheel.

- Common in robotic cars, AGVs, and DIY mobile platforms.

- Saves assembly time, optimized for traction.

- Includes a rubber/plastic wheel mounted on the shaft.

With Brake

- Halts and holds motor position when power is turned off.

- Ideal for elevators, electric locks, lifting systems.

- Prevents back-driving or unwanted movement under load.

- Electromagnetic brake mounted to the motor.

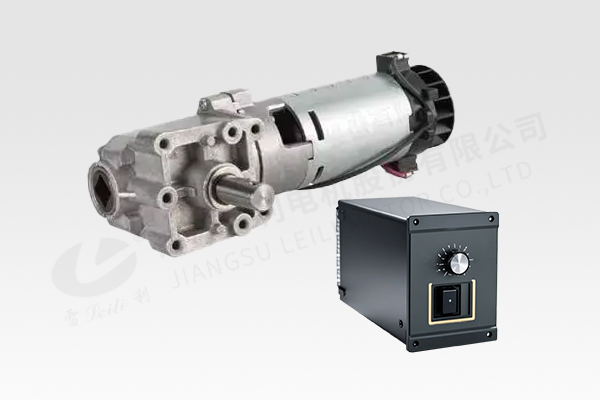

With Controller

- Comes with an integrated or matched control board.

- Used in systems needing plug-and-play control (e.g., speed, direction).

- Simplifies setup and reduces need for separate driver.

- Often includes PWM input or adjustable speed knob.

Featured Products

25ZYJ370 DC Brushed Gear Motor

- Rated Voltage: 12V

- Reduction Ratio: 1/198

- No Load Speed: 75r/min

33ZYJ360 DC Brushed Gear Motor

- Rated Voltage: 12V

- Reduction Ratio: 1/50

- No Load Speed: 96r/min

36ZYJ555 DC Brushed Gear Motor

- Rated Voltage: 24V

- No Load Speed: 215±10%r/min

- No Load Current: ≤0.6A

37ZYJ365 DC Brushed Gear Motor

- Rated Voltage: 12V/24V

- Reduction Ratio: 1/30

- No Load Speed: 161/120r/min

Applications

DC brushed gear motors are super versatile and widely used in applications that need low-speed, high-torque motion. Here’s a breakdown of their typical uses:

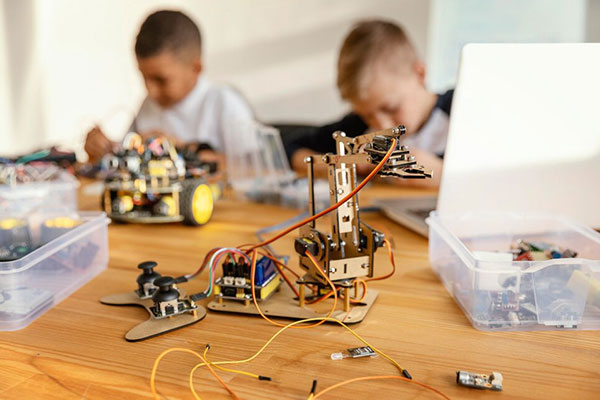

Toys & Hobby Projects

- Remote-controlled cars

- Motorized figures and gadgets

- STEM/DIY robotics kits

Consumer Electronics

- Printers and scanner

- Electric toothbrushes

- Automatic curtain systems

Robotics

- Mobile robot drive systems

- Robot arms and joints

- Line-following and obstacle-avoiding bots

Automotive Systems

- Power windows and seat adjusters

- HVAC actuators

- Door locks and sunroof motors

Home & Office Automation

- Smart blinds and curtain openers

- Electric locks and latches

- Vending and coffee machines

Industrial Automation

- Conveyor belts

- Automated guided vehicles (AGVs)

- Actuators for simple machines

FAQ

1.What are a DC brushed gear motor's primary parts?

Motor housing, brushes, commutator, rotor (armature), stator, and gearbox.

2.What use does a gear motor's gear serve?

To boost torque output and decrease motor speed in heavy-duty applications.

3.What is the torque range of brushed gear motors?

It varies widely — from a few mNm for mini motors to several Nm for industrial ones.

4.How fast can a DC brushed gear motor spin?

Speeds range from <10 RPM (high torque) to >1000 RPM (low torque), depending on gear ratio.

5.How do I connect a DC brushed gear motor?

Connect the motor's two terminals to a DC power supply or motor driver module.

6.Can I use an H-bridge to control a brushed gear motor?

Yes, an H-bridge lets you control direction and speed efficiently.

7.Do DC gear motors need a driver?

For basic operation, no — but for PWM control or direction reversal, a motor driver is recommended.