Synchronous Motor Manufacturer

LEILI specializes in professional production and customization for various sizes of synchronous motors, such as PM and hysteresis motors, to meet your industry needs.

We provide high efficiency, precise speed control, and reliable performance, offering ideal solutions for Home appliances and industrial applications.

- Power: 1W-315kW

- Voltage: 12V-380V

- Rated Speed: 0.028RPM-3000RPM

By Excitation Method

Non-Excited

Non-excited synchronous motors use permanent magnets or inherent magnetic properties in the rotor, eliminating the need for an external excitation power source.

Permanent Magnet Synchronous Motor(PMSM)

- These motors don't require external stimulation because they create a magnetic field using permanent magnets on the rotor.

- Rated Voltage: 12V-380V

- Frequency: 50-500pps

- Rated Speed: 0.868-3000RPM

Reluctance Synchronous Motor

- These motors rely on the rotor's variable reluctance to align with the stator's magnetic field, providing efficient torque generation without permanent magnets.

- Rated Voltage: 100V to 600V

- Rated Frequency: 50Hz to 60Hz

- Rated Speed: 1,000 RPM to 6,000 RPM

Hysteresis Synchronous Motor

- These motors use the hysteresis effect in the rotor material, maintaining synchronization with the stator field, offering smooth and reliable operation.

- Rated Voltage: 24V-230V

- Rated Frequency: 50/60

- Rated Speed: 0.83RPM-6RPM

Excited

Excited synchronous motors require an external DC power supply to energize the rotor’s magnetic field for operation.

Hybrid Synchronous Motor

- Combines permanent magnet and reluctance motor features.

- Effective torque production at different speeds.

- Ideal for industrial applications and electric cars.

Reversible Synchronous Motor

- Operates in both directions (clockwise and counterclockwise).

- Used for applications requiring bidirectional motion.

- Offers precise speed and position control.

By Current

AC Synchronous motor

- Operates on AC, maintaining constant speed despite load changes.

- Requires a separate excitation system for rotor field generation.

- Commonly used in power plants, compressors, and industrial machinery.

- Offers high efficiency and precise speed control at constant frequency.

DC Synchronous motor

- Operates on DC, with fixed rotor speed synchronized to frequency.

- Requires a commutator and brushes to maintain current in the rotor.

- Used in precise positioning, robotics, and servo applications.

- High torque can be produced at low speeds.

By Phase

Single Phase

- Single-phase synchronous motor needs additional starting mechanisms due to no rotating field.

- Used in low-power applications like small appliances.

- Less efficient and prone to stability issues.

Three Phase

- Three phase synchronous motor provides a continuous rotating magnetic field for self-starting.

- More effective and dependable in industrial settings.

- Ideal for high-power devices like pumps and compressors.

By Starting Methods

Using Pony Motors

- Small motor starts synchronous motor.

- Once speed is reached, disengage pony motor.

- Common in small synchronous motors.

Using Damper Winding

- Damper winding provides initial starting torque.

- Rotor speed synchronizes once damper winding fades.

- Common in large synchronous motors.

As a Slip Ring Induction Motor

- Initially works as an induction motor.

- Rotor is started through slip rings and external resistance.

- Changes to synchronous operation once motor reaches speed.

Using Small DC Machine Coupled to It

- Small DC motor provides initial excitation for synchronization.

- After reaching speed, DC motor is disconnected.

- Ensures stable start for larger synchronous motors.

Featured Products

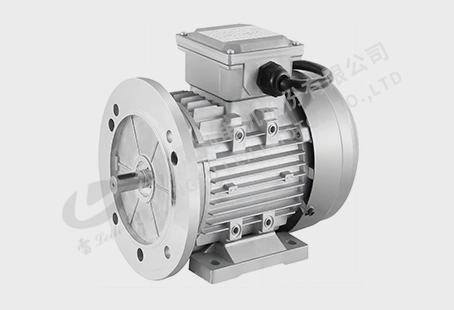

0.75KW PMSM Motor

- Rated Voltage: 220-380V

- Rated Current: 1.6-2.8A

- Rated Torque: 2.39-4.78N·m

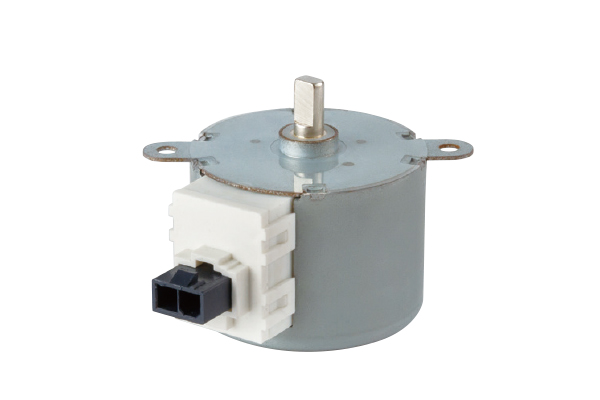

TJB3-X Hysteresis synchronous Motor

- Rated Voltage: AC24V

- Rated Current:≤400mA

- Rated Power: ≤5W

TJB2-X Hysteresis synchronous Motor

- Rated Voltage: AC230V

- Rated Current:≤30mA

- Rated Power: ≤6W

Applications

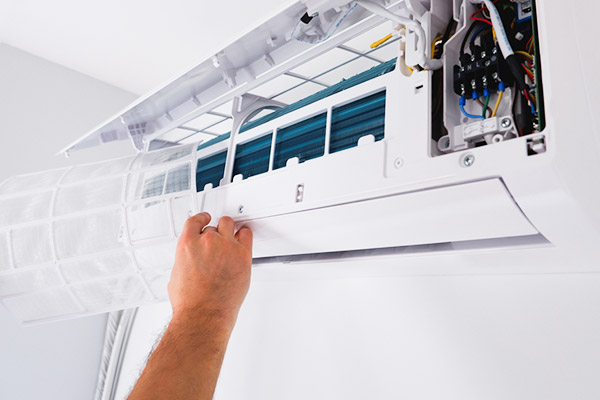

Synchronous motors are widely used in power generation, providing stable, precise speed for applications like electric propulsion in ships, large compressors, and HVAC systems. They ensure consistent operation in time-critical machinery such as clocks and industrial conveyor systems.

- Power Generation

- Electric Propulsion

- Clocks and Timepieces

- HVAC Systems

- Conveyor Systems

- Pumps and Compressors